This is something that comes up every day in my line of work: IIC [and STC] ratings of floor-ceiling assemblies. I get calls from homeowners, architects, contractors, developers, product distributors- pretty much anyone involved in flooring whether they’re on the design side, sales side, or construction side. Almost always, it goes the same way:

Customer: I need to reach IIC — (usually it’s a 50 to reach code minimum, but sometimes it’s a 60).

Which underlayment should I use?

This is where I try my hardest not to sound disinterested or condescending, because I really don’t feel that way- it just requires a conscious effort not to sound robotic when you’ve gotten used to asking the same questions. Chances are, other acoustic consultants may have a similar experience, so here’s some sound advice to prepare yourself with before you contact an acoustic consultant.

- IIC and STC ratings are dependent on entire assemblies, not any single element.

This means that you’ll need to have all of the details of your floor-ceiling assembly before you can expect real advice from an acoustician. Ideally you’ll have an architectural drawing calling out each element and it’s thickness in the assembly, but if not, I usually email a list like this for them to fill out:

– Floor Finish

– Underlayment

– Subfloor system (concrete slab? wood joist? truss? spacings, thicknesses, gauges, etc.)

– Batt insulation in the ceiling cavity?

– Resilient channels?

– Ceiling details (material, number of layers, thicknesses?) - The science of predicting IIC and STC ratings has not been perfected.

Much to the dismay of many people, acousticians can’t just add a couple of numbers together to determine your assembly’s predicted IIC rating. Believe it or not, there is no set formula or equation out there that will accurately predict these ratings. Currently, the only absolute way of determining a rating is by testing the actual assembly. Even then, there are still many factors that can prevent you from obtaining an accurate rating. Also, due to inevitable variations in construction conditions, one assembly’s rating should not be considered representative of another assembly, even an identical one. This often-overlooked caveat is specified in the detailed description of the IIC test (ASTM standard E492). It is, however, helpful to use test results as reference points of what you can expect from identical or similar assemblies. With all this said, even the best prediction is likely to come with a +/- 3 dB window of uncertainty. - More is not necessarily better.

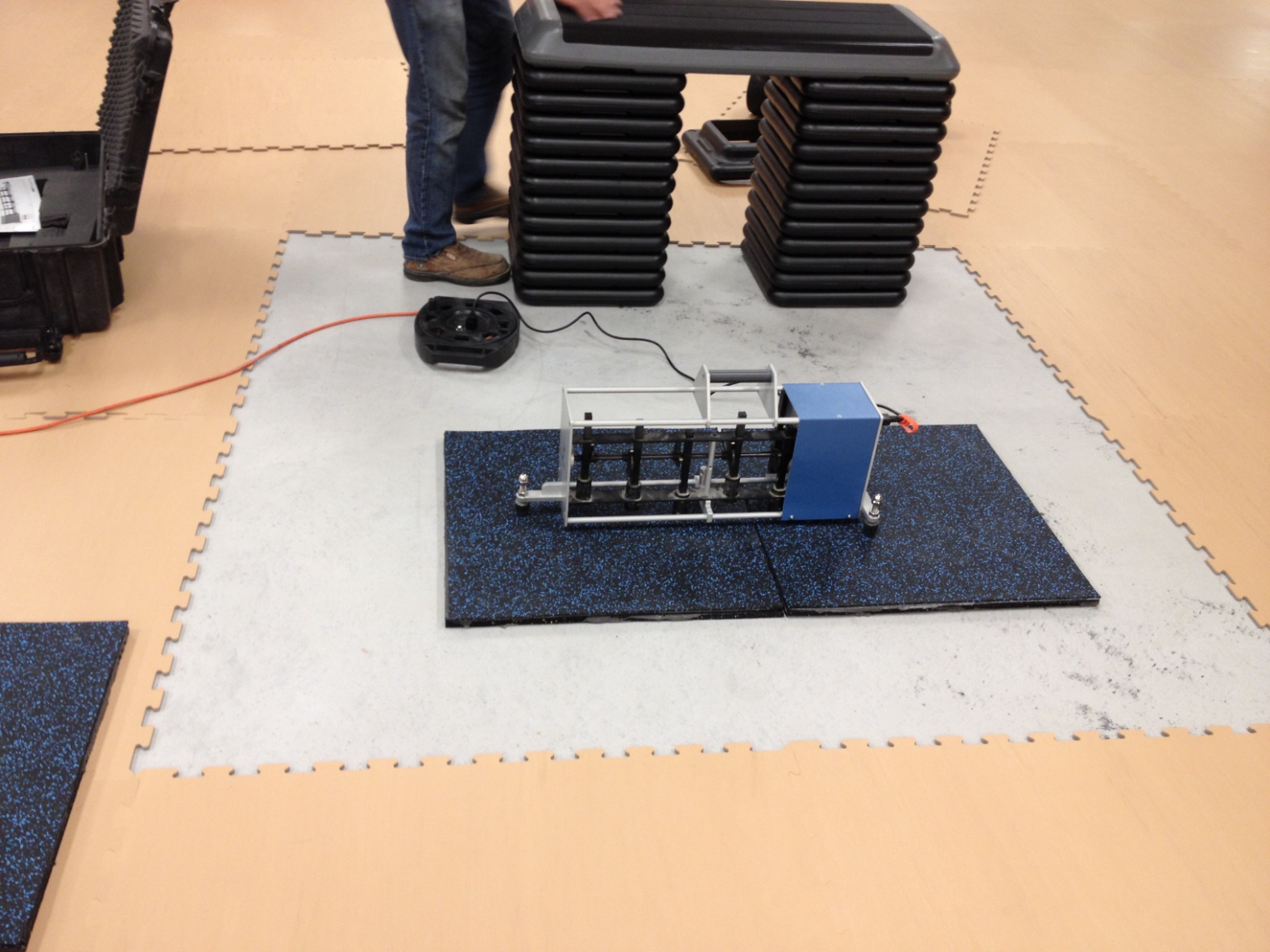

Of particular interest to IIC ratings my company, ECORE, manufactures flooring underlayments. One common misconception is that using an increased thickness of an underlayment will definitely result in a better IIC rating. While this is generally true, this is a good time to familiarize yourself with the law of diminishing returns. Wikipedia defines this in the context of economics, but it’s also applicable to the physics of IIC ratings. The initial doubling of a material will yield the highest return on value. For example, suppose a 2mm underlayment improves an assembly’s IIC rating by 12 points. Doubling it to 4mm might give you another 3-5 points of improvement. Increasing the thickness beyond that point might add another 1-2 points for a few more millimeters, but you will see the amount of improvement begin to plateau with the increased thickness. - Sometimes, you’re just gonna have to add a ceiling.

With the current trend of converting old factory buildings into residential units or hip restaurants, everybody wants to leave the decks exposed. Unfortunately, in most cases, it’s going to be difficult to achieve a code-minimum IIC 50 rating by only treating the floor-side of the assembly. Either way, it’s all about physics. If you want to prevent sound from being transmitted from one space to another, your best bet is by adding mass. The most common ways of achieving this are by adding either an inch or more of gypsum concrete or by adding a suspended ceiling below.

The above items should get you off to a good start with appropriate expectations when reaching out to an acoustical consultant for help with your IIC ratings. Good luck, and as always, we’re just here to provide some Sound Advice. Please let us know how we’re doing.

This is could not be more correct. Great advice!!

Great point about more not always being better. I didn’t realize the improvement level isn’t as high as you add more underlayment. I will be sure to consider these things before I hire an acoustical consultant. Thanks for sharing!