Press Release: Ecore & Pliteq Lawsuit Settled

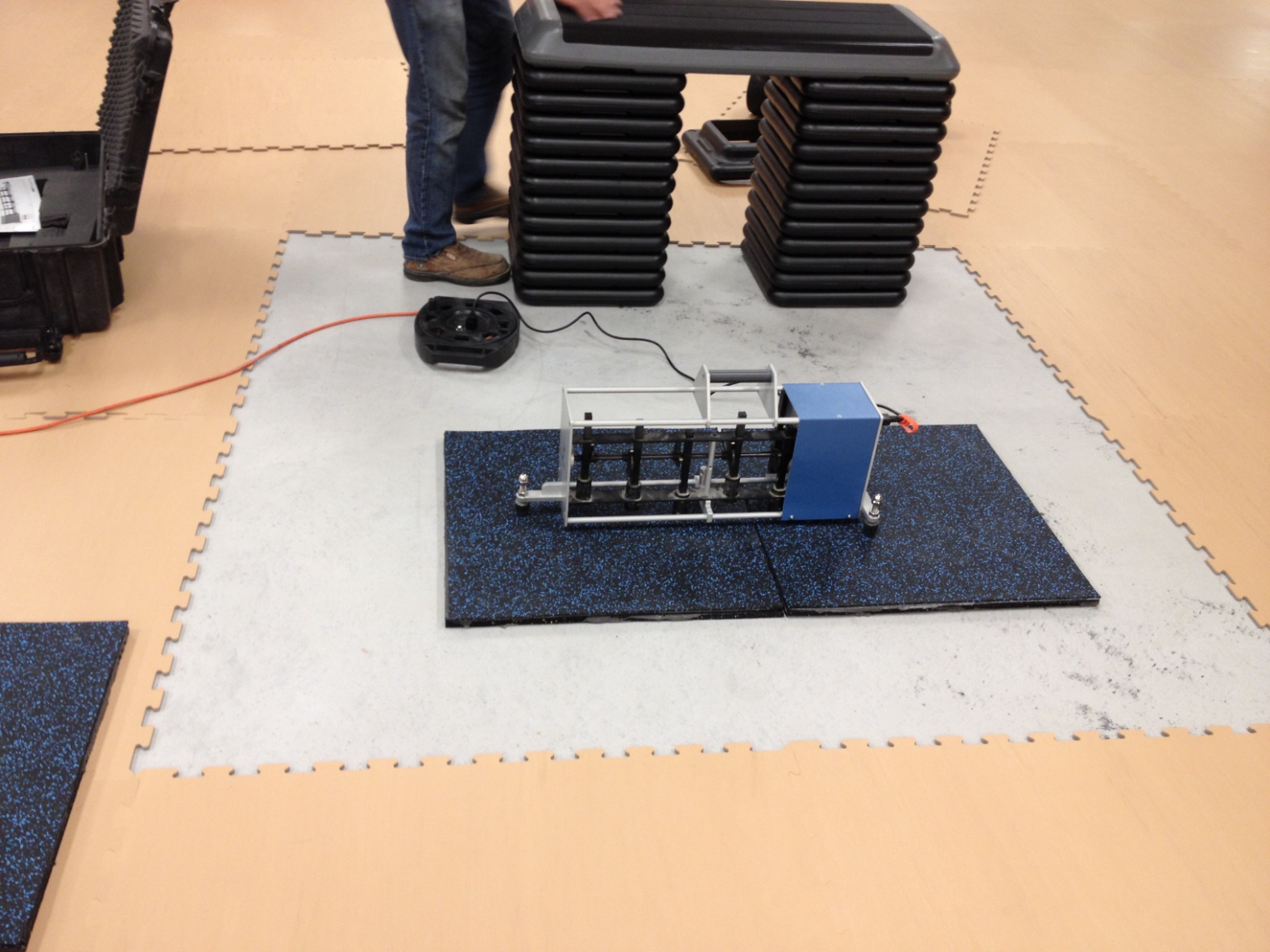

Ecore, a company that transforms reclaimed waste into unique performance surfaces, has successfully settled a lawsuit against Paul Downey and Pliteq, a business that sells building products for commercial sound control. The lawsuit arose as a result of Pliteq buying Ecore products through third parties and selling those products as its own manufactured product. “We discovered that Paul Downey and Pliteq were having third parties buy our products and having them shipped to a warehouse in Allentown, Pa.,” said Arthur Dodge, III, President and CEO of Ecore. “We learned from an employee of that warehouse that Pliteq was instructing the warehouse to take the Ecore labels off of our products and replace the Ecore labels with labels identifying the products as being manufactured by Pliteq.” Pliteq was simultaneously representing on the Pliteq Web site that the material was manufactured by it in Lancaster, Pa. Once Ecore learned of the relabeling activity, the company initiated a lawsuit against both Downey and Pliteq. A federal judge issued an immediate order requiring Downey and Pliteq to stop the activity of identifying the Ecore manufactured product as being made by Pliteq, which Pliteq agreed to. Ecore’s lawsuit continued and, shortly before trial, Ecore and Pliteq settled. Downey and Pliteq agreed to never engage in the activity of relabeling or representing any of Ecore’s products, including Ecore’s manufactured sound control underlayment, as their own products or implying that Ecore’s products were manufactured by them. “We are pleased to put this matter behind us and ensure (more…)